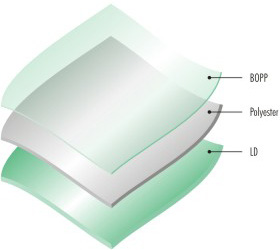

We produce the multilayer PP film which is with homo-polymer and co-polymer used as a heat seal layer along with BOPP/Polyester film in a laminate for packing of various articles. Our products are glossier and more transparent with higher strength, superior barrier properties and excellent sealing strength.

METALIZED CPP FILM

METALIZED CPP FILM  NATURAL CPP FILM

NATURAL CPP FILM  WHITE OPAQUE CPP FILM

WHITE OPAQUE CPP FILM METALIZED CPP FILM

METALIZED CPP FILM NATURAL CPP FILM

NATURAL CPP FILM WHITE OPAQUE CPP FILM

WHITE OPAQUE CPP FILM

Cast Polypropylene (CPP) Films

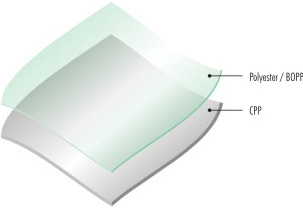

Cast polypropylene film usually known as CPP Film is universally used in packaging products. CPP is becoming

more popular and attractive packaging material for many products compared to other packaging films. Our range

includes mainly transparent, metallised and opaque CPP films. FDA approved resins are used in making our CPP

films which are safe for food packaging.

This is a multilayer PP film with homo-polymer and co-polymer used as a heat seal layer along with

BOPP/Polyester film in a laminate for packing of various articles. CPP films are glossier and more transparent

with higher strength, superior barrier properties and excellent sealing strength.

Key Features

Advantages

DESCRIPTION

| Product Type | Thickness | Application |

| 3 Layer Heat Sealable Natural Treated Lamination grade CPP Film | 18 to 80 Micron | Food and confectionary, Oil and Lube, Detergent & Shampoo, Textile etc. |

| 3 Layer Both Side Heat Sealable Natural CPP Film | 18 to 80 Micron | Pouch & Bag. |

| 3 Layer File & Folder CPP Film | 80 Micron | File & Folder etc. |

| 3 Layer File Blister CPP Film | 80 Micron | Pharmaceutical Tablet, disposable syringe, needles and medical appliances blister packing, General Cosmetic, Confectionary blister packing. |

| 3 Layer Both Side Side Treated Natural CPP Film | 18 to 80 Micron | Food and Snacks Packaging. |

| PROPERTIES | TEST METHOD | UNIT | Typical Values | ||||

| 20 | 22 | 25 | 30 | ||||

| GENERAL | |||||||

| Thickness | Internal | Micron | 20 | 22 | 25 | 30 | |

| Gauge | 80 | 88 | 100 | 120 | |||

| Film Density | D-1505 | gm/cc | 0.91 | 0.91 | 0.91 | 0.91 | |

| GSM | Internal | gm/m2 | 18.2 | 20.02 | 22.75 | 27.3 | |

| Yield | Internal | m2/kg | 54.94 | 49.95 | 43.95 | 36.63 | |

| Treatment Level** | (Min) | D-2578 | dyne/cm | 40 | 40 | 40 | 40 |

| Coef. of Kinetic Friction | (Max) | D-1894 | 0.18-0.22 | 0.18-0.22 | 0.18-0.22 | 0.18-0.22 | |

| Haze | D-1003 | % | 1.8-2.0 | 2-2.5 | 2-2.5 | 2-2.5 | |

| Gloss | 45° | D-2457 | % | 86 – 89 | 86 – 89 | 86 – 89 | 86 – 89 |

| MECHANICAL | |||||||

| Tensile Strength at Break (Min) | MD* | D-882 | kg/cm2 | 600-700 | 650-750 | 700-800 | 700-800 |

| 170-200 | 190-220 | 250-300 | 250-300 | ||||

| Elongation at Break | MD* | D-882 | % | 450 | 500 | 600 | 650 |

| 700 | 700 | 750 | 750 | ||||

| THERMAL | |||||||

| Heat Seal Initiation Temperature |

Internal | °C | 116 | 116 | 118 | 118 | |

| Heat Seal Strength (Min) | Internal | gm/ 25 mm |

2000 | 2200 | 2600 | 3100 | |

| BARRIER | |||||||

| O2 (23°C & 0%RH) | D-3985 | (cc/100 in2/24hr) |

239 | 235 | 233 | 230 | |

| H2O(38°C & 90%RH) | F-1249 | (gm/100 in2/day) |

0.84 | 0.82 | 0.77 | 0.67 | |